Fine Fiber Glass Factory L.L.C

Established in 2001, Fine Fibre Glass Factory LLC is one of the leading manufacturers of GRP products in the United Arab Emirates. We Design, Manufacture and Supply high quality products to fit for the signified purpose and as per the customer requirement in UAE and other GCC Countries.

Our Vision

The company is well organized with all facilities to provide a prompt and efficient service for all its customers. Adequate experience, commitment towards the customers, product quality and the after-sale support enhanced the company to be the prime establishment in UAE since 2001.

We improvise keeping innovative technology in mind, our premium division which thrives to bring in performance based composite products.

Our Mission

- Achieving sustainable business growth in the field of composites

- Exploring and implementing advanced technologies in our processes

- Driving innovation through new concepts, designs, products, and solutions

- Integrating Environmental and Social Sustainability factors into our business decisions

Our Core Values

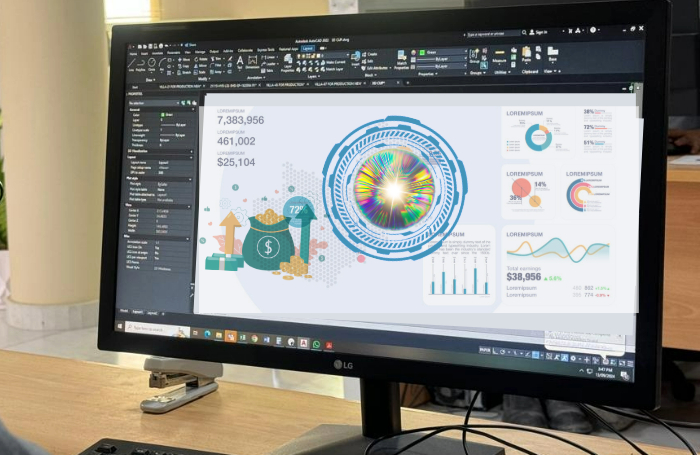

Under the strategic leadership of our stakeholders, the company excels at catering to the needs of the local market, of which a major share comes from the manufacturing of the pools for our prestigious clients, who have supplied and installed above 2500 pools, all of them mostly customized designs.

We have a 5000 sq.m. manufacturing facility in the new industrial area Umm Al Quwain, which houses 220 workers to assist in production and installation works.

Raw materials are key to the quality of finished products in manufacturing. We'll look at how the source and properties of these materials affect the final product.

04.Our Process Technologies

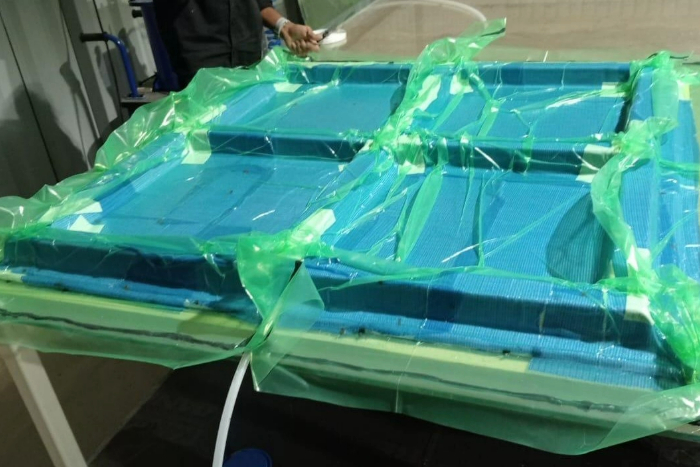

Vacuum infusion

Vacuum infusion uses a vacuum to pull resin into a laminate, making it a great method for producing large, strong, lightweight structures that also reduce emissions.

Dream to have big! Free Consultation and Lets Do It!

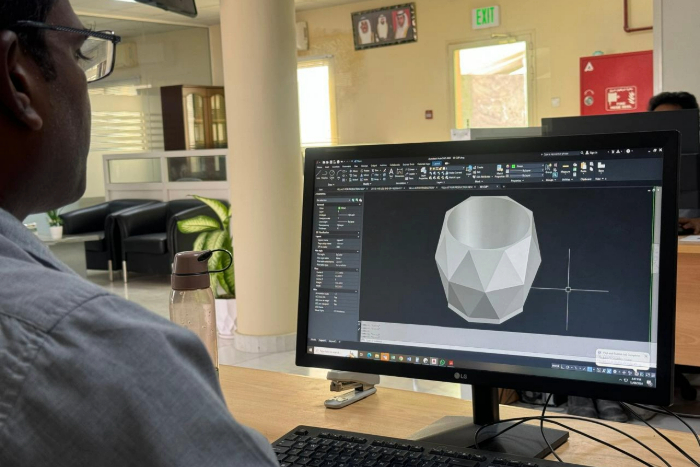

04.Design & Prototype

Our drafting and design team has the capability to design and manufacture pressure vessels and tanks and pools as per Section-X, BS-EN-13121, or BS-EN-13923. We also conduct FE analysis on STAAD PRO software.

Also conduct material testing as per ASTM Standards like D3039, D3418, D3518, D792, D2344, etc.